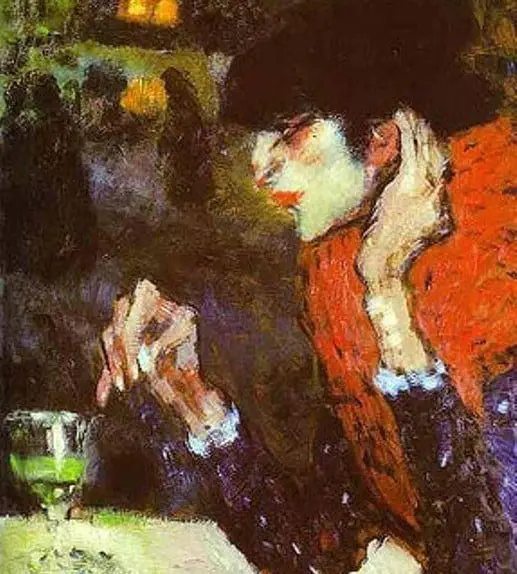

Absinthe has a long and rich history that dates back to the late 18th century. It was a popular drink among artists, writers, and intellectuals during this time period because absinthe was thought to enhance creativity.

The absinthes of today are typically much less potent than the absinthes of yesteryear. In many countries, it is not legal to make your own absinthe without being a licensed distillery. Today there are many brands of absinthe available for purchase including Lucid, Kubler, Pernod, and more.

But how is absinthe made? What is the process that creates the enchanting green liquid that has inspired some of the greatest creative minds in history?

Today we’re diving in and learning just how the magic happens!

Absinthe Ingredients

For fine absinthe, it’s important to have fine ingredients!

Absinthe itself is very herbal with a complex bouquet of oils, scents, and flavors.

The exact measurements of herbs used by distillers are, of course, kept secret. However, there are some inclusions that are necessary for all absinthes and common in many.

Before we even talk about the absinthe-making process itself, let’s look at the two most important parts of the finished product!

Herbs and the “Holy Trinity”

The herbs used to produce absinthe are of particular importance. First things first, we have what is called the “Holy Trinity.”

This “Holy Trinity” consists of grand wormwood (artemisia absinthium), fennel, and green anise. To be considered true absinthe, all three of these must be present.

Other herbs are commonly added in addition to the Holy Trinity. Exactly which herbs are used depends on the maker’s taste and the type of flavor profile that they are trying to achieve.

Some common herbs used in making absinthe include:

- hyssop

- star anise

- petite wormwood (artemisia pontica)

- coriander

- angelica root

It is becoming increasingly common to find absinthes that also include herbs such as spearmint, lemon balm, stinging nettles, and calamus.

Some, especially absinthes rouges (red absinthes), will add floral notes by including flowers like hibiscus. This is largely a newer method, though it’s becoming more popular with absinthes such as La Cascade Rouge.

As long as the Holy Trinity is there, there are tons of herb combinations that can be explored by distillers!

Recommended: How to Properly Prepare Absinthe (Beginner Friendly Guide)

Alcohol Base

Most absinthes are made with a wine spirit or brandy base. This is due to the abundance of white grapes in regions where absinthe was historically made as well as the fact that the wine base gives the absinthe a better quality than other bases.

The wine base is the most classic option when distilling absinthe.

However, alcohol made from grains, molasses, and beets can also be used. These were particularly used when the Great French Wine Blight destroyed vineyards throughout France and Europe in the mid-19th century.

Generally speaking, wine bases have a better time bonding with the oils from the herbs. Rather than being starkly neutral, the end result becomes a seamless marriage between the alcohol base and the herbs.

Potent Potables: The Absinthe Making Process

Now that we’ve covered the key ingredients used when making absinthe, let’s move on to examining the process!

Maceration

The journey begins with the initial maceration step.

Here, the first batch of herbs is left to soak in the high-proof spirits for some time (usually around 8-10 hours.) Gentle heat (usually around 40 degrees Celcius, 104 degrees Fahrenheit) is applied with gentle mixing.

The goal here is to get the oils and flavor of the herbs to release into the spirits.

Once this initial maceration process is finished, the distiller stops the heat and waits a few hours before resuming production.

Currently, this pure spirit is too strong, crude, and young to drink. It now has to be distilled!

Distillation

With the first maceration step completed, we move to the distillation step of the process.

In this step, the water is separated from the oils and spirits. This is achieved by evaporating the alcohol and herbal oils. As these are evaporated, they travel as steam to the cooling coil where they reform into a liquid state through condensation.

When this step is done, you have two elements in two separate chambers: the absinthe (which is currently clear but does contain the herbs’ flavors) and the leftover water and plant bits that are no longer useful.

If you’ve ever seen absinthe referred to as a blanche (white) or la bleue (blue), this is what that is. The absinthe itself is clear but filled with the flavors and aromas of the herbs used to make it.

Related: You can learn more about the styles of absinthe by clicking here!

Second Maceration

For most absinthes, we now come to the second maceration step. This is where we see our beloved Green Fairy really spring to life!

Adding in more herbs like hyssop, petite wormwood, lemon balm, and coriander helps to really round out the absinthe’s aroma and flavor. Not to mention it’s where we see it take on that lovely green hue from the herbs’ chlorophyll!

This works similarly to the first maceration step: gentle heat and mild agitation for several hours.

For this to work properly, the alcohol still has to be very high-proof. That is what allows the herbs’ oils to bond with the alcohol and create a cohesive color and flavor that will last.

Of course, even once this step is finished you have something that is so highly alcoholic that it couldn’t be consumed.

That means it’s time to move to the proofing step!

Proofing

With the second maceration completed (unless it was a blanche being made in which case we skipped that step), we come to the proofing stage.

In this step, water is added to the absinthe to reduce the percentage of alcohol. Most commonly, an absinthe will end somewhere in the 60-70% ABV range.

It may sound like a simple process, but, with so much work having already gone into the absinthe, it’s one that needs to be done carefully!

Some distilleries use a reverse osmosis system for this step. Not only are they bringing the absinthe to the desired ABV, but they are also filtering out any minerals or particulate that has sneaked through the process up to this point.

Aging

Before absinthe is ready to be bottled and sold, it’s allowed to age for several months.

This allows the flavor of the absinthe to develop and mature. Most absinthes are aged in barrels that won’t alter the flavor though there are some brands who have taken to aging absinthe in whiskey barrels.

Most absinthes are aged for around 6 to 7 months before being bottled. However, some may be bottled as soon as just a few months while others might age for over a year.

Related: How To Properly Store Your Absinthe

Other Production Methods

It’s worth covering a couple of other methods that are sometimes used to make absinthe.

These are different from the distillation method that we’ve already covered and don’t result in the same quality of finished product.

Cold Distillation / Cold Compounding

Some absinthe makers use a method similar to the old prohibition practice of making “bathtub gin.”

With this method, the herbs are dried then soaked in strong ethyl alcohol. As they soak, the herbs are macerated over the next day or two.

From there, the mixture is filtered and water is added to make it drinkable.

The key problem with this method is that, without any heat used to extract the absinthe’s flavor and color, it ends up being very weak.

It also doesn’t result in absinthe with the same depth of herbal flavor that you get from traditional distillation methods. Without proper distillation, it’s a vastly inferior product that does not contain any of the rich complexities of a true distilled absinthe.

Absinthe made this way may even be artificially colored to try and mimic the absinthe that is made with traditional distillation methods.

Furthermore, the end product of this method is so bitter that it’s not uncommon for the maker to add tons of sugar to the mixture.

Absinthe brands who are trying to keep their prices low have been known to use this cheap alternative production method. This is absolutely a case of “you get what you pay for!”

My two cents: any absinthe made this way is only absinthe in the loosest of terms.

Oil Mix

Last but not least we get to the lowest of the low: adding essential oils or concentrated syrups to neutral alcohol and calling it “absinthe.”

It’s not absinthe in even the broadest sense. To be honest, I’m not entirely sure what this kind of abomination could (and probably should) be called.

These are absinthe impostors in the very worst sense of the phrase.

They are absinthe only in that they are green, but they are spirits in name only. It’s not even an exaggeration to call them Franken-spirits since there is no absinthe involved in their production.

You can usually spot these very easily: they’re incredibly cheap and typically some kind of obnoxious color.

Avoid these like the plague.

Homemade Absinthe: Yes or No?

So should you make absinthe at home?

If you’re in the United States at least, you should absolutely not. I’ll have to do research on other countries’ regulations.

In the US, you cannot distill spirits without the proper permits.

This leaves using Cold Distillation or Oil Mix methods to make “absinthe” but you simply will not be able to make a product that is genuinely good with these techniques.

Since absinthe became legal again and has seen a resurgence since the late 2000s, it’s not uncommon to find kits online that promise to sell you everything you need to make your own absinthe.

Don’t bother.

These kits are designed to take advantage of absinthe enthusiasts who don’t know any better.

Absinthe is not supposed to be made at home and should only ever be distilled. If you want absinthe, buy it from a reputable store. Not only will it taste better, but it’s also safer for you!

Besides, the last thing you want to do is poison yourself!

Conclusion – How Is Absinthe Made

Making absinthe requires a blend of science, art, experience, patience, and passion. Each glass has a story to tell through its ingredients, production process, and presentation.

I hope that this article has helped you appreciate the time-honored tradition that goes into crafting the perfect absinthe!

Curious why your absinthe is changing color in the bottle? Check out my article that explains what that’s all about!